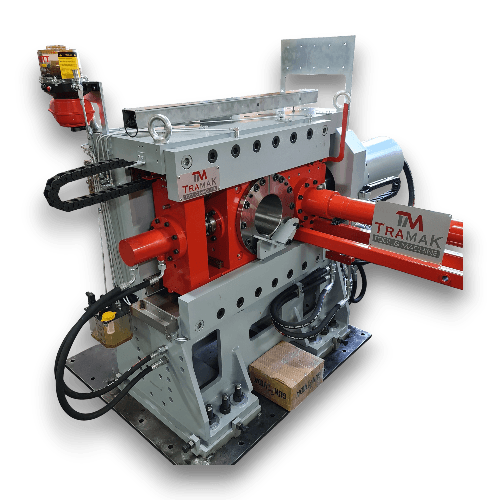

Hot Log Shear Machine

The TRAMAK Hot Log Shear processes a high quality cut as result of its sophisticated design:

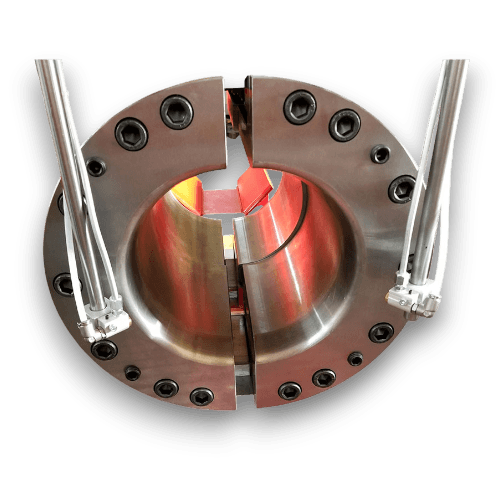

- Optimised movements during clamping.

- Special design and strict tolerances of the clamps.

- Low distance between cutting edges.

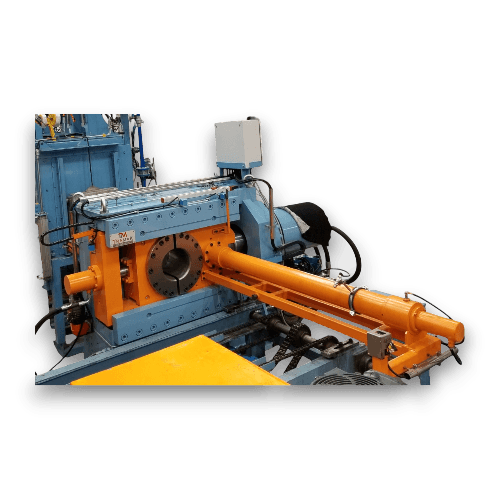

The function of the hot shear is to cut from the preheated ingot (length: 4 – 8 m) a billet for the extrusion press. The billet length can be chosen in function of the production

Advantages against pre-cut billet:

The plant manager, know using pre-cut billets, should install a hot shear in the future because:

- Raw material (ingot with length 4 -8 m) is much cheaper than pre-cut billet and,

- Billet length can be chosen “just-in-time” so the productivity is higher.

- Greater use of the bar.

Advantages against log saw:

The plant manager, know using log saw, should install a hot shear in the future because:

- Hot shear operates without noise emission at very short cycle times,

- No chips will be produced (material waste) + the log rest can be used as well

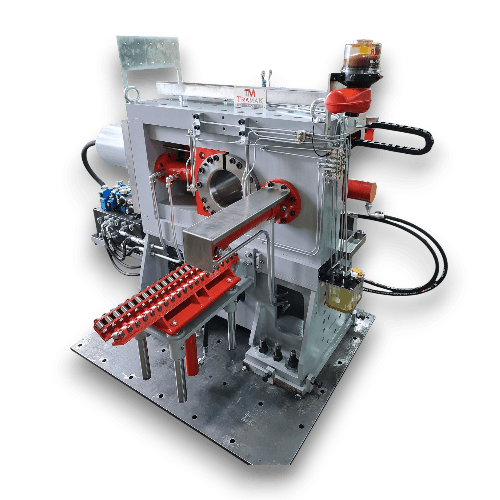

- Hot shear, hydraulic powered, is formed by the fixed body and the movable sides, inside of which are mounted the cutting tools. All that is mounted on top of a metallic welded support.

- Special design and strict tolerances of the clamping system that allows having a very clean cut with minimum deformation on the billet end diameter and a flat vertical surface at both ends. The half clamps open/close by help of hydraulic cylinders.

- The Tramak hot shear cut is within a horizontal plane avoiding the need of lifting the cut billet up to the extrusion height.

- Automatic lubrication system for clamps to assure the cut quality.

- Billet rest optimisation program that allows working with two piece billets as if it was a continuous log feeding and minimizing the scrap to zero.

- There are two transfer cylinders of the two cut piece billets. One piece is come back to the logs furnace and the other one is led to the billets feeder.

- Automatic lubrication system for the friction between the moving parts of the machine thus ensuring proper maintenance and a long life of the components.

- Also there is automatic knife/blade nozzle lubrication.

Would you like to learn more about our machines?

If you provide us with your information via the form below, we can carefully share information about the machines with you.