Tool

TRAMAK EXTRUSION TOOLING SOLUTIONS

The efficiency of extrusiona depends to a large extent on the performance of the tooling, in particular on its service life. The durability of the extrusion tooling is influenced mainly by the following four factors:

• Tool design

• Material selection and heat treatment

• Tool manufacture

• Working conditions

These are clear criteria for the competence and selection of a partner. The alloy steel specialist TRAMAK is recognised worldwide as a leading supplier to the extrusion industry. TRAMAK has acquired extensive expertise over a number of years through innovation and reliable products that go far beyond the criteria in this branch of industry. Based on many years of cooperation with the extrusion industry, TRAMAK is regarded as a problem solver and partner that can be relied upon for sound advice.

TRAMAK specialist engineers are internationally involved in the development and design of new tools and processes.

MATERIAL SELECTION FOR EXTRUSION TOOLING

The material selection depends primarily on the following factors:

• Material being extruded (aluminium, copper and copper alloys, steel)

• Press temperature (up to 1000°C, partly long contact times)

• Extrusion program/press sequence

• Billet dimensions

• Type of press

• Extrusion speed

• Press power

• Extruded profile

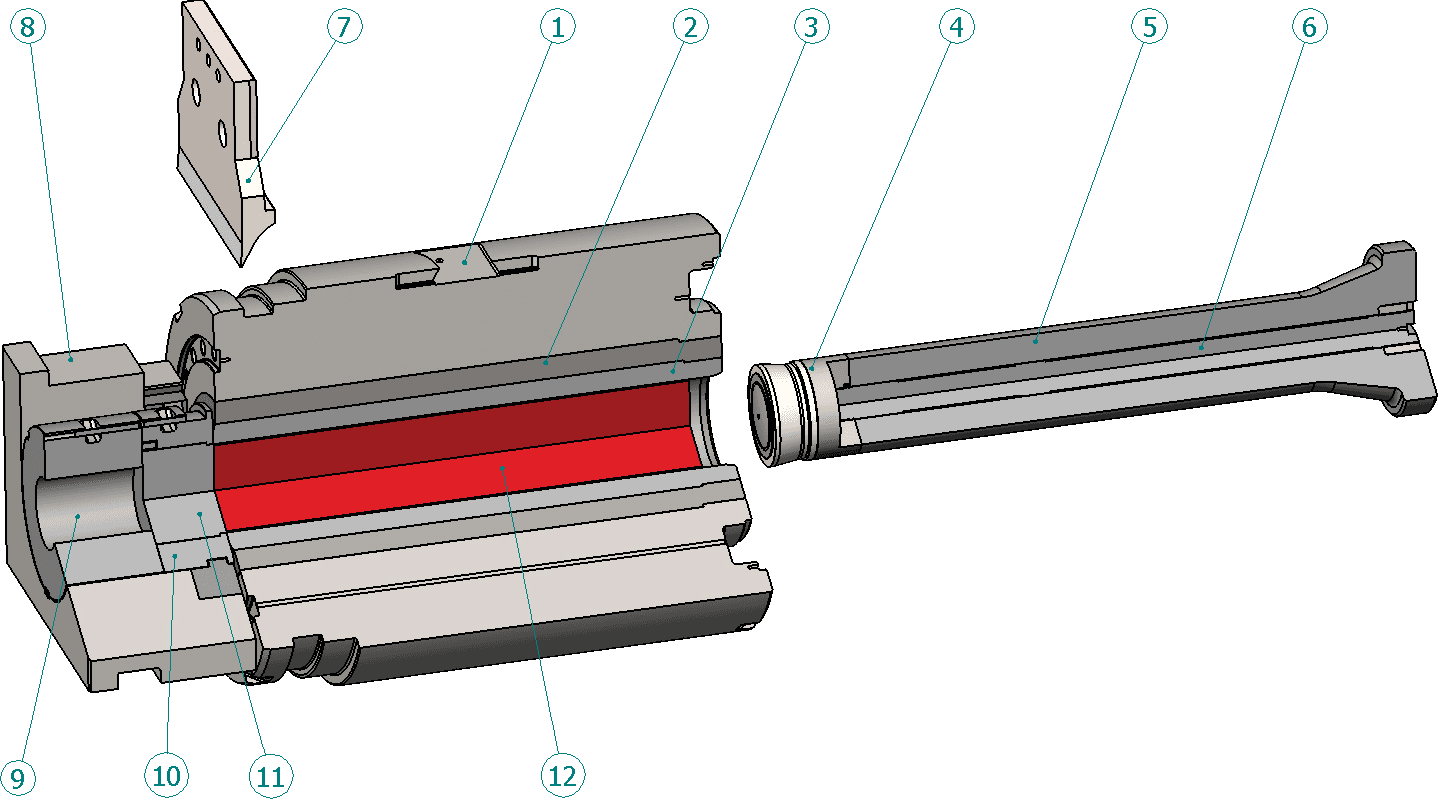

TOOLING OF A METAL EXTRUSION PRESS

1- Mantle

2- Liner Holder

3- Liner

4- Dummy Block

5- Stem

6- Rod or Mandrel

7- Shear Blade

8- Tool Holder

9- Bolster

10-Die Holder

11- Die

12- Billet

TOOL LIFE

Heat Treatment

Tool Design

Handling / Maintenance

Surface Condition

Tool Steel Quality

Mechanical Load , Termal Stress

Chemical Composition Of The Meterial To Be Processed